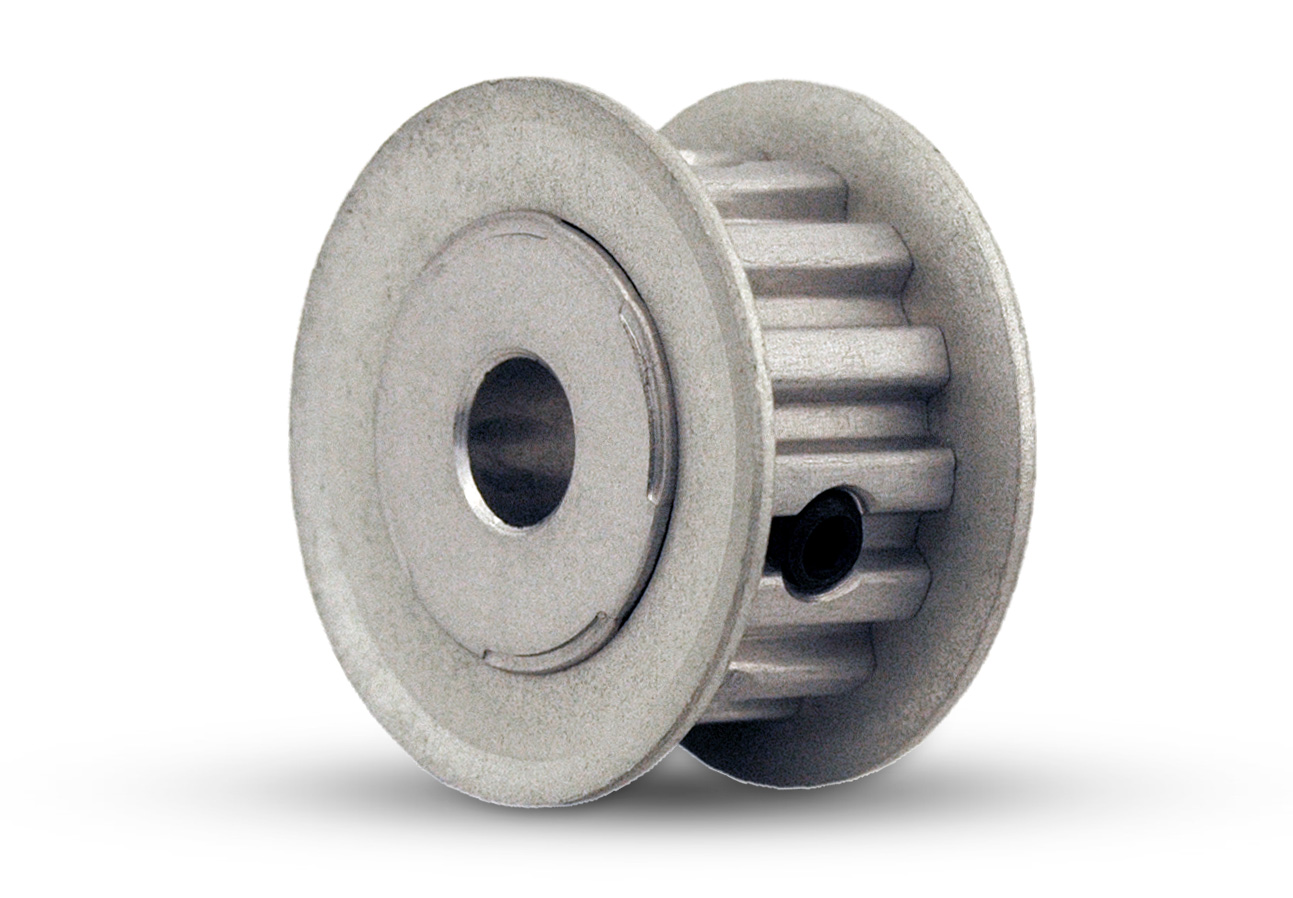

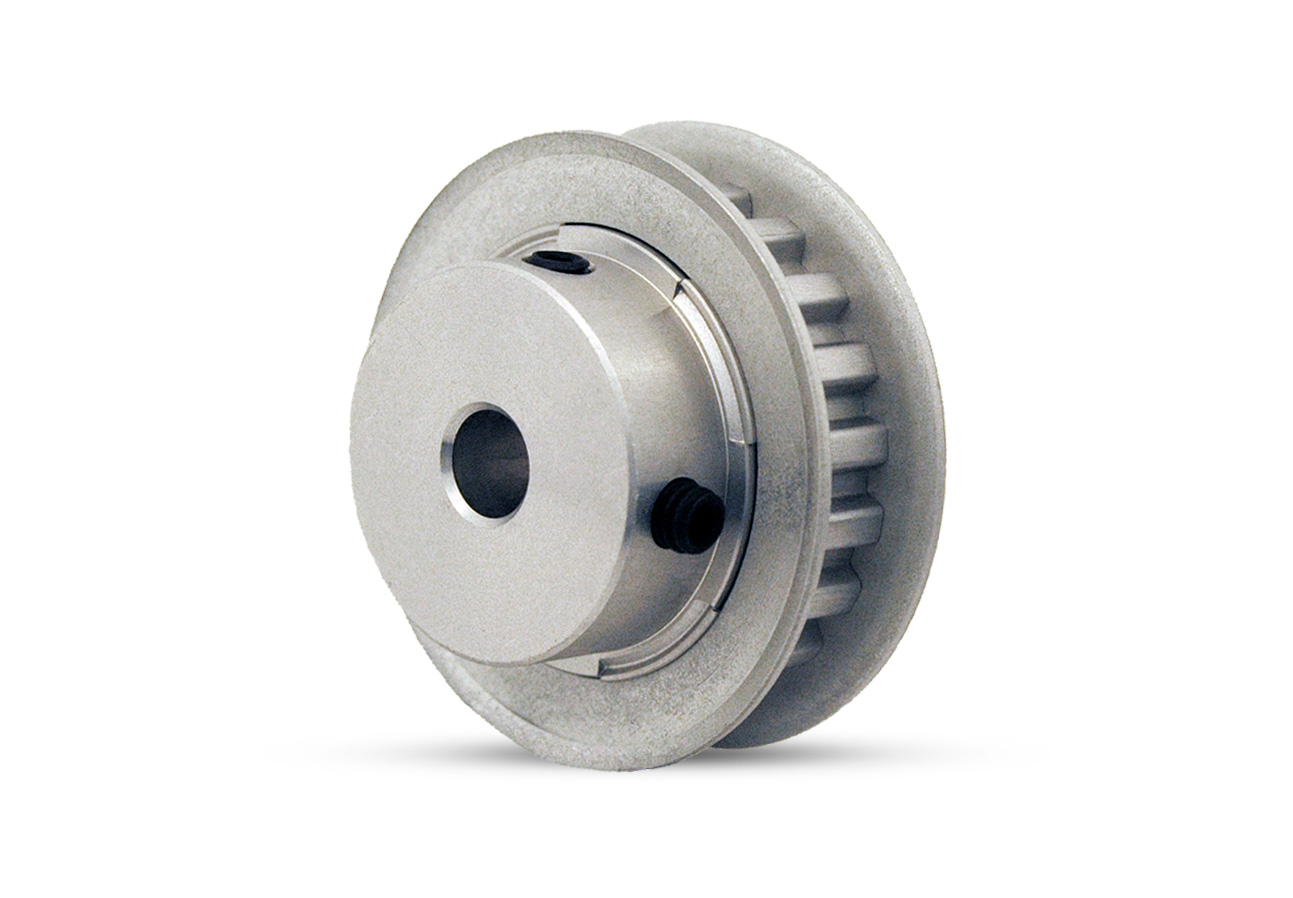

Product Description

Aluminium Timing Pulley Mxl XL L H Xh Xxh T2.5 T5 T10 At5 At10 Gt2 3m 5m 8m Timing Belt Pulley

| Product Name | Timing Belt Pulley |

| Teeth Quantity | 10-150 teeth or customized |

| Teeth profile | MXL, XXL, XL, L, H, XH, XXH |

| T2.5, T5, T10, T20 | |

| HTD3M, HTD5M, HTD8M, HTD14M, HTD20M, Gt2 | |

| S2M, S3M, S4.5M, S5M, S8M, S14M | |

| Inner Bore | 2-200mm H7 precision or customized |

| Surface treatment | Anodize,Black Oxide and Galvanization |

Main Products:

Timing belt pulleys, timing bars, timing belt clamping plates.

Locking elements and shrink discs: could be alternative for Ringfeder, Sati, Chiaravalli, BEA, KBK, Tollok, etc.

V belt pulleys and taper lock bush.

Sprockets, idler, and plate wheels.

Gears and racks: spur gear, helical gear, bevel gear, worm gear, gear rack.

Shaft couplings: miniature coupling, curved tooth coupling, chain coupling, HRC coupling, NM coupling, FCL coupling, GE coupling, rigid and flexible coupling, jaw coupling, disc coupling, multi-beam coupling, universal joint, torque limiter, shaft collars.

Forging, Casting, Stamping Parts.

Other customized power transmission products and Machining Parts (OEM).

Advantage:

1. Factory directly supply , we can continue to provide a stable supply

2. Many years manufacture experience , top quality guaranteed by skilled workers, managing system and status of facilities.

3. Competitive and reasonable price

4. OEM service, we can do as your drawings or samples

5. Quality Guarantee, 100% inspect before delivery

6. Good after-sale service, Our wokers are all professional and all can speak English.

7. Timely delivery, We have many long cooperation supplier. supply ONE-STOP service

8. High-tech CNC Machines

9. Independent Engineering Department

10.Kinds of surface treatment—Zinc Plating, Powder Coating, Anodizing, Chrome Plate, RoHs .etc .

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Customizable |

| Manufacturing Process: | Forging, Casting |

| Material: | Aluminum, Steel, Cast Iron, Brass |

| Surface Treatment: | Anodize, Black Oxide, Phosphate and Galvanizat |

| Application: | Chemical Industry, Grain Transport, Industrial Transmission, Textile Machinery |

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can XL pulleys be customized or modified for specific industrial needs?

Yes, XL pulleys can be customized or modified to meet specific industrial needs. Here’s a detailed explanation of how XL pulleys can be tailored for specific requirements:

1. Size and Configuration:

XL pulleys can be customized in terms of size and configuration to match the requirements of different industrial applications. The diameter, width, and overall dimensions of the pulleys can be adjusted to accommodate specific belt sizes, space constraints, or desired power transmission ratios. Customization in size and configuration ensures optimal fit and performance within the given system.

2. Material Selection:

The choice of materials for XL pulleys can be customized based on the operating conditions and environmental factors of an industrial application. For example, if the pulleys will be exposed to corrosive chemicals, materials with high corrosion resistance, such as stainless steel or specialized coatings, can be selected. Customized material selection ensures the pulleys can withstand the specific demands of the application.

3. Surface Coatings and Treatments:

To enhance the performance and longevity of XL pulleys, various surface coatings and treatments can be applied. These include coatings for improved wear resistance, low friction coatings to reduce energy loss, or specialized treatments for better grip or bonding with the timing belt. Customized surface coatings and treatments allow for specific performance enhancements based on the industrial needs.

4. Timing Belt Compatibility:

XL pulleys can be customized to ensure compatibility with specific types of timing belts. This involves designing the pulley’s tooth profile, pitch, and tooth spacing to match the corresponding timing belt’s specifications. Customization in timing belt compatibility ensures optimal engagement between the pulleys and belts, resulting in efficient power transmission and reduced wear.

5. Specialty Features:

XL pulleys can be customized with specialty features to address unique industrial needs. These features may include integrated flanges for belt tracking, keyways or set screw holes for secure shaft attachment, custom hub configurations for easy mounting, or special profiles to accommodate additional accessories or components. Specialty features provide added functionality and convenience in specific industrial applications.

6. Performance Optimization:

By understanding the specific requirements of an industrial application, XL pulleys can be customized to optimize their performance. This may involve modifying the pulley’s geometry, tooth profile, or tooth count to achieve desired torque transmission, speed ratios, or power requirements. Performance optimization ensures efficient operation and reliable performance in the intended application.

The ability to customize or modify XL pulleys for specific industrial needs allows for tailored solutions that meet unique requirements. Manufacturers or designers work closely with customers to understand their application demands and provide customized pulleys that deliver optimal performance, reliability, and efficiency.

Are there safety considerations when working with XL pulley systems?

Yes, there are several safety considerations that should be taken into account when working with XL pulley systems. Here are some important safety considerations:

1. Lockout/Tagout Procedures:

Before performing any maintenance or repair tasks on a power transmission system involving XL pulleys, it is crucial to follow proper lockout/tagout procedures. This involves isolating the system from its power source and ensuring that it cannot be energized accidentally. Lockout/tagout procedures help prevent unexpected startup of the system, which could cause serious injuries.

2. Personal Protective Equipment (PPE):

Wear appropriate personal protective equipment when working with XL pulley systems. Depending on the specific task and potential hazards, PPE may include safety glasses, gloves, hearing protection, and protective clothing. PPE helps protect against potential injuries from contact with moving parts, flying debris, or noise exposure.

3. Training and Competence:

Ensure that personnel working with XL pulley systems are adequately trained and competent to perform their tasks safely. They should be familiar with the proper procedures for installation, operation, and maintenance of the pulleys. Training should also cover the identification and understanding of potential hazards associated with the system and how to mitigate them.

4. Machine Guards:

Install appropriate machine guards and protective enclosures around the XL pulley systems to prevent accidental contact with moving parts. Guards help minimize the risk of entanglement, pinch points, or injuries caused by the rotating pulleys or the timing belt.

5. Risk Assessment:

Conduct a thorough risk assessment of the XL pulley system and its surrounding environment. Identify and evaluate potential hazards, such as pinch points, sharp edges, or electrical hazards. Implement control measures to mitigate the identified risks, such as implementing interlocks, providing warning signs, or establishing safe work procedures.

6. Regular Maintenance:

Perform regular maintenance and inspection of the XL pulley system to ensure its safe operation. This includes checking for any signs of wear, damage, or misalignment, as well as verifying the integrity of guards and safety devices. Address any maintenance issues promptly to prevent potential safety hazards.

It is important to consult relevant safety standards, guidelines, and regulations specific to your industry and jurisdiction when working with XL pulley systems. Adhering to these safety considerations will help protect personnel from injuries and create a safe working environment when interacting with XL pulley systems.

Can you explain the key characteristics and specifications of XL pulleys?

XL pulleys have specific characteristics and specifications that are important to understand for their proper selection and use. Here are the key details:

1. Tooth Profile:

XL pulleys have a tooth profile designed to work with XL timing belts. The tooth profile is trapezoidal in shape, with specific dimensions and angles to ensure precise engagement with the corresponding teeth on the timing belt.

2. Pitch Size:

The pitch size of an XL pulley refers to the distance between adjacent tooth centers. XL pulleys have a standardized pitch size of 0.200 inches (5.08 mm). This pitch size ensures compatibility with XL timing belts of the same pitch, allowing for easy interchangeability.

3. Belt Width Compatibility:

XL pulleys are designed to accommodate XL timing belts of specific widths. The belt width is determined by the application requirements and load considerations. XL pulleys are available in various groove widths to match the corresponding XL timing belt width, ensuring proper belt engagement and power transmission.

4. Material and Construction:

XL pulleys are commonly made from materials such as aluminum, steel, or plastic. The choice of material depends on factors like the application requirements, load capacity, and cost considerations. The pulleys are precision-machined to ensure accurate tooth profiles, smooth operation, and reliable performance.

5. Number of Teeth:

The number of teeth on an XL pulley determines the speed ratio and the positioning accuracy of the motion control system. The number of teeth can vary depending on the specific application requirements and the desired speed and torque ratios.

6. Flange Options:

XL pulleys may come with flanges on one or both sides. Flanges provide additional support to the timing belt, preventing it from slipping off the pulley during operation. The presence and configuration of flanges depend on the specific application needs and the desired level of belt stability.

7. Application Range:

XL pulleys are suitable for applications that require precise motion control, such as robotics, CNC machines, 3D printers, and other automated systems. They can handle moderate to high torque requirements and operate at various speeds, depending on the specific pulley size, material, and construction.

8. Interchangeability:

Due to standardized pitch sizes and tooth profiles, XL pulleys from different manufacturers are interchangeable with XL timing belts of the same specifications. This interchangeability simplifies replacement, maintenance, and system upgrades.

Understanding these key characteristics and specifications of XL pulleys is essential for selecting the right pulley for a given application, ensuring proper power transmission, and achieving accurate motion control.

editor by CX

2024-05-06