Product Description

| Certification | ISO9001:2018 SGS TS16949 |

| Quality | 100% Inspection |

| Machining equipment |

CNC maching,CNC Turning, CNC Milling ,CNC center machine, auto lathe machine, Wire-cutting Machine CNC punching machines, CNC bending machines CNT stamping machine, CNC/auto lathe machine , Drilling machine, Hydraulic machine,Riveting machine , Tapping machine, welding machine, Film attaching machine Aluminum extrusion machine,Casting machine,Plastic injection machine,etc. |

| Materials |

Aluminum, Steel, SPCC, SGCC,SECC, SPTE,Stainless steel, Brass, Copper, Bronze, ABS, PC, PO, POM, Nylon, etc. |

| Surface finish |

Anodized, Oxide, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the heat disposing, hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated, blue black zinc-plated,rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Inspection Equipment |

CMM, Projection, Calipers, Micro caliper, Thread Micro caliper, Pin gauge, Caliper gauge, Pass meter, Pass meter etc. |

| Drawing formation | PDF, CAD/DWG/DXF, IGS/STP etc. |

We focus on CNC processing ,cold heading and casting and sheet metal machining services, with more than 150 processing equipment and professional testing equipment, and several professional engineers. We focus on developing the field of hardware parts and provide customers with OEM and ODM services. Through years of accumulation, we have accumulated rich experience and inventory. Our customers have spread all over the world. In order to meet the requirements of different customers, we are constantly expanding our Production capacity and R&D capacity, look CHINAMFG to cooperating with you.

1.We have Specialized QC testers to check the products quality according to customers’ needs.

2.We have IQC to check the dimensions and surface of the incoming material.

3.We have PQC to inspect full-course during the processing.

4.We have FQC to inspect all the plating products from outsides and make the 100% inspection before the shipments.

FAQ

Q1: Why choose ZheJiang n?

To provide our customers with first-class services in the supply of quality screws minimizing costs.

Q2: How is quality ensured?

All our processes strictly adhere to ISO9001:2018 procedures. We have strict quality control from producing to delivery. Our company had strong technology support, 80% of our colleagues are master or bachelor’s degree. We have cultivated a group of managers who are familiar with product quality , good at modern concept of management.

Q3: Can You Strictly Follow The Tolerance on The Drawing And Meet The High Precision?

Yes, we can, we can provide high precision parts and make the parts as your drawing.

Q4: How should I order and make payment?

By T/T, for samples 100% with the order; for production, 30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment. negotiation accepted.

Q5: What’s your Delivery Time?

Standard parts: 7-20days

Non-standard parts: 15-25days

We will make the delivery as soon as possible with the guarantee quality

Q6:How to Custom-made (OEM/ODM)?

If you have a new product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

Q7:Which mode of transport would be better?

In general, the product are heavy, we advice to make delivery by sea, Also we respect your views of other transportation as well.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

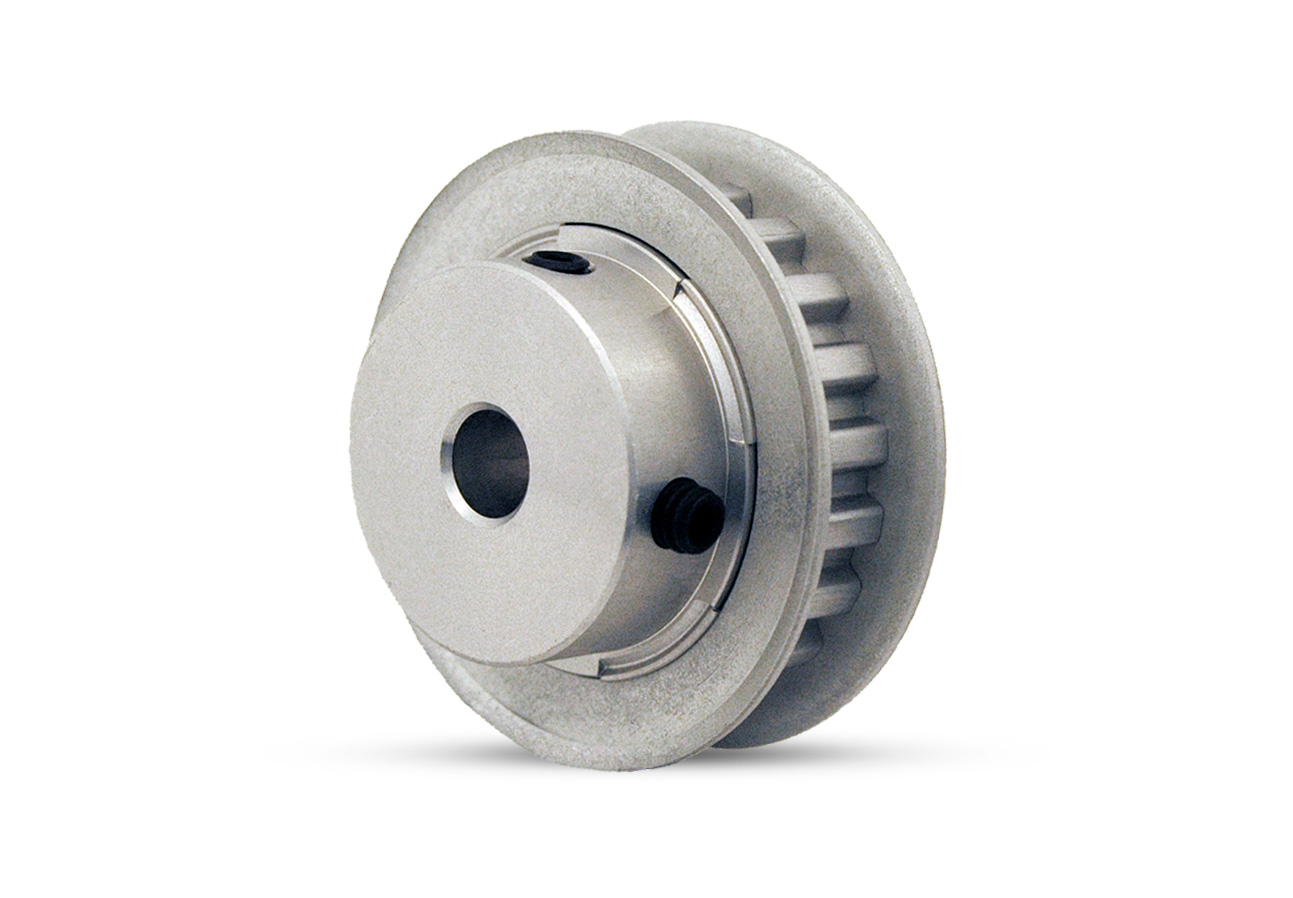

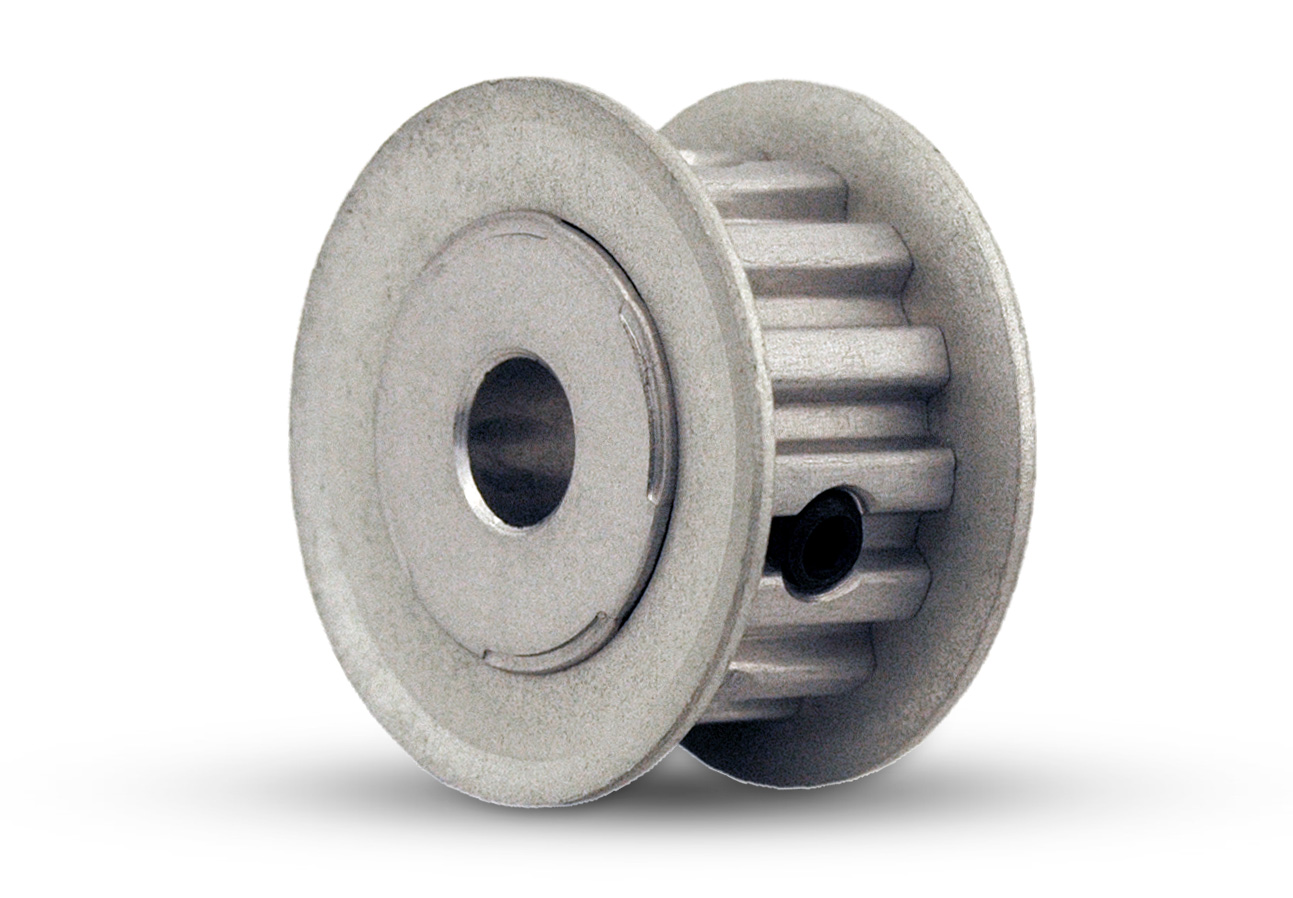

| Pulley Sizes: | Custom |

| Manufacturing Process: | CNC Machinng |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Order Sample Custom

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do XL pulleys compare to other pulley types, such as HTD or V-belt pulleys?

XL pulleys, HTD pulleys, and V-belt pulleys are all popular types of pulleys used in mechanical systems. Here is a detailed comparison of XL pulleys with HTD and V-belt pulleys:

1. Tooth Profile:

XL pulleys and HTD (High Torque Drive) pulleys both utilize toothed belts for power transmission. The main difference lies in their tooth profiles. XL pulleys have trapezoidal teeth, while HTD pulleys have a curvilinear tooth profile. V-belt pulleys, on the other hand, are designed for V-belts, which have a wider, wedge-shaped cross-section.

2. Power Transmission Capacity:

XL pulleys and HTD pulleys offer higher power transmission capacities compared to V-belt pulleys. The toothed belt designs of XL and HTD pulleys provide a positive engagement, preventing slippage under higher loads or torque. V-belt pulleys rely on friction between the belt and pulley, limiting their power transmission capacity.

3. Speed Capability:

XL pulleys and HTD pulleys are both suitable for higher speed applications compared to V-belt pulleys. The toothed belt designs allow for better grip and reduced belt slippage, enabling XL and HTD pulleys to operate at higher rotational speeds without compromising performance. V-belt pulleys are generally suitable for lower speed applications.

4. Efficiency:

XL pulleys and HTD pulleys offer higher efficiency compared to V-belt pulleys. The positive engagement between the toothed belts and pulleys in XL and HTD systems minimizes slippage and associated energy losses. V-belt pulleys, relying on friction, may experience higher energy losses due to belt slip.

5. Precision and Positioning:

XL pulleys and HTD pulleys provide better positional accuracy and reduced backlash compared to V-belt pulleys. The toothed belt systems offer improved control and synchronization, making them suitable for applications that require precise positioning or timing, such as robotics or CNC machines.

6. Noise and Vibration:

XL pulleys and HTD pulleys generally produce less noise and vibration compared to V-belt pulleys. The toothed belt systems exhibit smoother operation due to their positive engagement, reducing noise and vibration levels. V-belt pulleys may generate more noise and vibration due to potential slippage and belt oscillation.

7. Installation and Maintenance:

XL pulleys, HTD pulleys, and V-belt pulleys are all relatively easy to install and maintain. However, V-belt pulleys may require more frequent tension adjustments and periodic belt replacements due to belt wear and stretch. Toothed belt systems, including XL and HTD pulleys, often require less maintenance and offer longer belt life.

8. Application Suitability:

The choice between XL pulleys, HTD pulleys, and V-belt pulleys depends on the specific application requirements. XL and HTD pulleys are commonly used in industrial automation, power transmission, and precision machinery applications that demand higher torque, speed, and accuracy. V-belt pulleys are often employed in applications such as HVAC systems, automotive engines, and smaller machinery.

In summary, XL pulleys, HTD pulleys, and V-belt pulleys have differences in tooth profile, power transmission capacity, speed capability, efficiency, precision, noise/vibration levels, installation/maintenance, and application suitability. Understanding these differences is crucial in selecting the most appropriate pulley type for a given mechanical system and its specific requirements.

How does the tooth profile of XL pulleys contribute to their performance?

The tooth profile of XL pulleys plays a crucial role in determining their performance in power transmission systems. Here’s a detailed explanation of how the tooth profile contributes to their performance:

1. Efficient Power Transmission:

The tooth profile of XL pulleys is designed to engage with the corresponding teeth on the timing belt. This positive engagement ensures efficient power transmission by minimizing slippage and maximizing the transfer of rotational motion. The tooth profile allows for a large contact area between the pulley and the belt, enabling effective torque transfer and minimizing energy losses.

2. Accurate and Repeatable Positioning:

The tooth profile of XL pulleys enables accurate and repeatable positioning in motion control systems. The teeth on the pulley mesh precisely with the teeth on the timing belt, providing precise angular displacement and positioning control. This tooth engagement allows for reliable and consistent positioning, making XL pulleys suitable for applications that require high positional accuracy, such as robotics and CNC machines.

3. Reduced Backlash:

The tooth profile of XL pulleys helps reduce backlash, which is the play or clearance between the teeth of the pulley and the belt. Backlash can introduce inaccuracies and vibrations in the power transmission system. The tooth profile of XL pulleys minimizes backlash by ensuring a close fit with the timing belt teeth, resulting in smoother operation, improved precision, and reduced mechanical vibrations.

4. Load Distribution:

The tooth profile of XL pulleys allows for effective load distribution along the width of the belt. As torque is transmitted from the pulley to the belt, the tooth profile ensures that the load is evenly distributed across the belt’s width. This load distribution helps prevent concentrated stress points and excessive wear on specific areas, leading to improved durability and longevity of the pulley and belt.

5. Noise Reduction:

XL pulleys with well-designed tooth profiles contribute to reduced noise levels during operation. The tooth engagement and smooth meshing between the pulley and the timing belt minimize vibration and noise generation. This advantage is particularly important in applications that require low noise levels, such as medical equipment, office machinery, and audiovisual systems.

Overall, the tooth profile of XL pulleys significantly impacts their performance by enabling efficient power transmission, precise positioning, reduced backlash, even load distribution, and noise reduction. Manufacturers carefully design the tooth profiles of XL pulleys to optimize these performance characteristics for various applications and operating conditions.

In which applications and industries are XL pulleys commonly used?

XL pulleys find extensive use in various applications and industries that require precise motion control and power transmission. Here are some common applications and industries where XL pulleys are commonly employed:

1. Robotics:

XL pulleys are utilized in robotic systems for precise positioning and movement control of robot arms, grippers, and other robotic components. They enable accurate and synchronized motion, allowing robots to perform complex tasks with precision.

2. CNC Machines:

CNC (Computer Numerical Control) machines, such as milling machines and lathes, rely on XL pulleys for precise control of spindle speed and tool positioning. The accurate motion provided by XL pulleys ensures high-quality machining and dimensional accuracy in CNC operations.

3. 3D Printers:

XL pulleys are commonly used in 3D printers to control the movement of the print head and the positioning of the build platform. The precise motion control facilitated by XL pulleys contributes to the accuracy and fine detail of the printed objects.

4. Automated Systems:

XL pulleys are employed in various automated systems, including conveyor systems, packaging machinery, assembly lines, and material handling equipment. These systems require synchronized and precise motion to ensure efficient and accurate operation.

5. Industrial Machinery:

In industrial settings, XL pulleys are used in a wide range of machinery, such as textile machines, printing presses, woodworking equipment, and industrial automation systems. They provide reliable power transmission and motion control in these demanding applications.

6. Automotive Industry:

XL pulleys are utilized in automotive applications, including engine timing systems, accessory drives, and power steering systems. The precise control and synchronization offered by XL pulleys contribute to efficient and reliable operation of these automotive components.

7. Medical Devices:

In the medical field, XL pulleys are found in equipment such as diagnostic machines, laboratory automation systems, and surgical instruments. They enable accurate movement and positioning, ensuring the precision required for medical procedures and diagnostics.

8. Aerospace and Defense:

XL pulleys are used in aerospace and defense applications, such as satellite positioning systems, guidance systems, and unmanned aerial vehicles (UAVs). The reliable motion control provided by XL pulleys is crucial for the accurate operation of these aerospace and defense systems.

9. Research and Development:

In research and development laboratories, XL pulleys are employed in experimental setups, prototyping systems, and testing equipment. Their precise motion control capabilities support the development and validation of new technologies and products.

In summary, XL pulleys are commonly used in applications and industries that require precise motion control and power transmission. Their versatility and reliability make them suitable for a wide range of applications, from robotics and CNC machines to 3D printers, automated systems, automotive components, medical devices, aerospace, and research and development.

editor by CX

2024-05-15