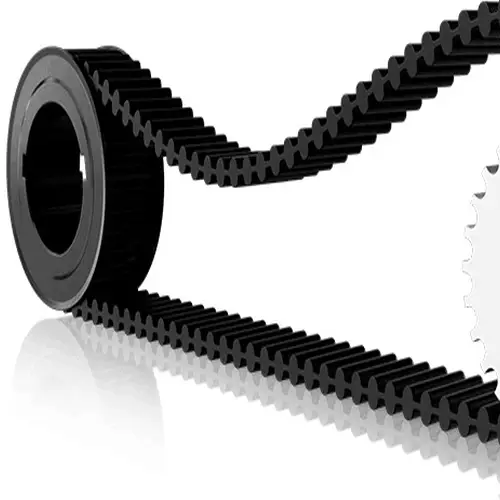

China Best Sales Alloy HTB Timing Belt Pulley S2m, S3m, L, H, XL, XH, XXH, HTD Wholesaler

Product Description

Our timing belt pulleys are manufactured to the highest standards, meeting both European and American standards. We offer a wide range of models, including XL037, L050, L075, L100, H075, H100, H150, H200, H300, XH200, XH300, XH400, HTD: 3M-09, 3M-15, 5M-09, 5M-15, 5M-25, 8M-20, 8M-30, 8M-50, 8M-85, 14M-40, 14M-55, 14M-85, 14M-115, 14M-170, T2.5, T5, T10, T20, AT2.5, AT5, AT10, and AT20.

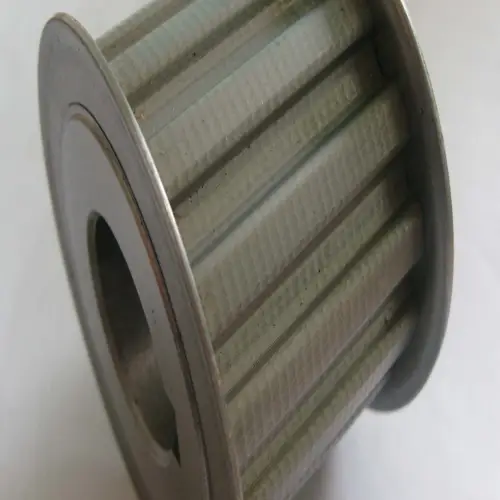

Our pulleys are available in various bore types, including pilot bore, taper bore, and QD bore. They are made from high-quality materials such as 1045 steel, aluminum, and stainless steel. The surface finish options include black oxidized phosphate, anodized, and zinc-plated. We also offer standard toothed bars for your convenience.

Detailed Photos

Our Advantages

- Comprehensive Product Portfolio: We offer a wide range of power transmission products, including drive chains, leaf chains, conveyor chains, agricultural chains, sprockets, and couplings. You can find everything you need in one place, saving you time and effort.

- Value Choice Products: Our products are known for their excellent quality and competitive prices. We provide the best combination of quality and affordability.

- Seasoned Sales Associates and Engineers: Our team consists of 15 experienced sales associates and 5 knowledgeable engineers who are always ready to assist you. They have industry expertise and will respond to your inquiries within 24 hours.

- 100% Customer Retention Rate: Our regular customers from around the world continue to choose us not only for our premium quality products but also for our superior services over the years.

Packaging & Shipping

FAQ

-

What is the average lead time for your products?

Our regular end-to-end lead time is 1-2 months, but we also provide express shipments for rush orders. Please consult our sales associate for more details.

-

Is your price better than your competitors for the same quality?

Definitely YES. We offer the most competitive prices in the power transmission industry. If you find a price disparity, we are more than happy to do a price match.

-

Can you produce chains according to my CAD drawings?

Yes, we can. In addition to regular standard chains, we specialize in producing non-standard and custom-designed products to meet specific technical requirements. We have a significant portion of our production capacity dedicated to manufacturing non-standard products.

-

Can I inspect the goods before shipment?

Absolutely. You or your representative, or any third-party inspection party you assign, are welcome to visit our facility and conduct inspections.

-

What payment methods do you accept?

We are flexible in terms of payment methods. We accept T/T, L/C, and various other online payment methods as long as they are applicable to your situation.

Our company specializes in supplying various industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in offering high-quality products, competitive prices, and excellent customer service. We also provide customization services based on your drawings and samples. Feel free to contact us for any inquiries or requests.

All the content of this page is from the Internet, and it is only intended as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier.

Performance Characteristics of Xl Pulley

Xl pulleys have several performance characteristics that make them highly desirable in various applications. Firstly, their high precision and accuracy ensure smooth and efficient operations. Secondly, they have excellent load-bearing capacity, allowing them to handle heavy loads without compromising performance. Thirdly, Xl pulleys are known for their durability and long lifespan, making them a cost-effective choice in the long run. Lastly, these pulleys offer low noise and vibration levels, resulting in quieter and more stable operations.

Types and Characteristics of Xl Pulley

Xl pulleys come in various types, each with its own unique characteristics. The most common types include timing belt pulleys, V-belt pulleys, and round belt pulleys. Timing belt pulleys provide precise power transmission and are widely used in applications that require accurate positioning. V-belt pulleys, on the other hand, excel in high-speed and high-torque applications due to their excellent grip. Round belt pulleys are versatile and can be used with various belt types, offering flexibility in different setups.

Advantages of Xl Pulley Materials

Xl pulleys can be made from different materials, each offering its own set of advantages. Aluminum pulleys are lightweight, corrosion-resistant, and suitable for applications where weight is a concern. Steel pulleys are highly durable and can handle heavy loads, making them ideal for demanding industrial applications. Plastic pulleys are lightweight, cost-effective, and offer excellent resistance to chemicals and moisture, making them suitable for various environments.

Application of Xl Pulley in Various Fields

The versatility of Xl pulleys makes them valuable across various industries. In the field of 3D printing, Xl pulleys are used for precise movement and positioning of printing heads, ensuring accurate and high-quality prints. In CNC machines, Xl pulleys are essential components for transmitting power and controlling the movement of cutting tools, enabling precise and efficient machining. Xl pulleys also play a crucial role in robotics, providing smooth and precise motion control. In office equipment, automotive systems, and many other fields, Xl pulleys are used for power transmission, ensuring smooth and reliable operations.

Future Development Trends and Opportunities

The future of Xl pulley products looks promising, with several development trends and opportunities on the horizon. The increasing demand for automation and robotics in various industries is expected to drive the need for high-precision pulley systems. Additionally, the growing popularity of 3D printing and CNC machining will create opportunities for the use of Xl pulleys in these fields. As technology advances, there will be a continuous need for more reliable, efficient, and durable Xl pulley solutions.

Choosing a Suitable Xl Pulley

When selecting an Xl pulley, it is crucial to consider several aspects to ensure optimal performance. Firstly, the load capacity of the pulley should match the requirements of the application to ensure smooth and reliable operation. Secondly, the material of the pulley should be chosen based on factors such as durability, weight, and resistance to environmental conditions. The diameter and size of the pulley should also be selected to suit the specific application. Additionally, the type of pulley and bore size are important considerations to ensure compatibility with the power transmission system.

In summary, Xl pulleys offer exceptional performance characteristics, come in various types with unique characteristics, and can be made from different materials to suit specific applications. Their value and importance can be seen across industries such as 3D printing, CNC machines, robotics, office equipment, and automotive systems. The future of Xl pulley products holds promising trends and opportunities. When choosing an Xl pulley, it is essential to consider factors such as load capacity, material, diameter and size, type of pulley, and bore size to ensure optimal performance.

Author: Dream